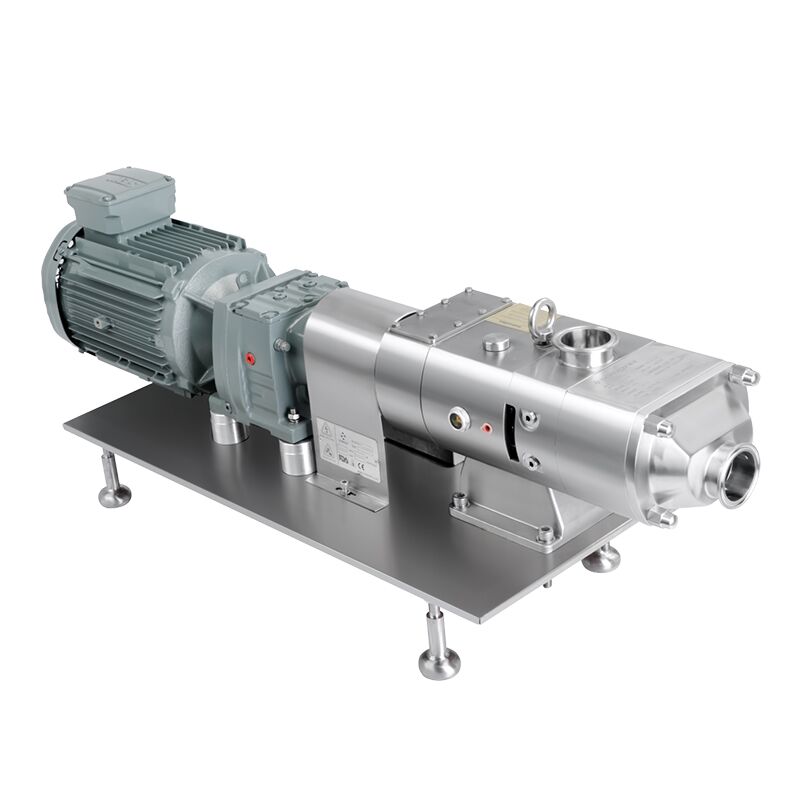

Sanitary Twin Screw Pump with Reducer & Motor

Donjoy Sanitary Twin Screw Pump is a positive displacement pump, robust construction, offers gentle product handling,pulse-free, quite and smooth, ideal for use to transfer high and low viscosity fluids or with solid. Hygienic design complied with US 3-A, FDA hygienic standard, widely used in the food processing, dairy, beverage, daily chemical and pharmaceutical industries…

Details about Sanitary Twin Screw Pump with Reducer & Motor

Specification

| Maximum Flow Rate | 110m3/h |

|---|---|

| Maximum pressure | 20 bar |

| Max Particles | 23mm |

| Speed range | 10-3500 R.P.M |

| Body Material | AISI SS316L (1.4404) |

| Body Types | Horizontal Type (TUL) & Vertical Type (TUR) |

| Temperature | -40 ° C to 150 ° C |

| Mechanical Seal | single seal SIC/SIC/EPDM (standard), double mechanical seal (option) |

| Motor Power Supply | 1.1KW-11KW, Wide voltage |

| Motor Brand | ABB motor, Simens Beide motor ,standard IEC |

| Surface treatment | Ra≤0.6μm; EP=Ra0.4μm |

| Certification | US 3-A 02-11, FDA21 CFR 177.2600, CE EN809:1998/A1 2009, EN60204-1:2006/A1:2009 |

| Connection type | Tri-Clamp End, Butt Weld End, Thread, Flange |

Sanitary Twin Screw Pump with Reducer & Motor

Donjoy Sanitary Twin Screw Pump is a positive displacement pump, with robust construction, offering gentle product handling,pulse-free, quiet and smooth, ideal for use to transfer high and low viscosity fluids or with solids. Hygienic design complied with US 3-A, FDA hygienic standard, widely used in the food processing, dairy, beverage, daily chemical and pharmaceutical industries…

Sanitary Double Screw Pump Description

Donjoy double screw pump is not only used for fluid extraction and transportation but also applicable of CIP and SIP systems, it reduces pipeline, valve control, CIP dedicated pumps, improve efficiency and reduce costs. The pump features other positive displacement pumps do not have, such as pulse-free, no damage to particles, high pressure, large speed and flow range.

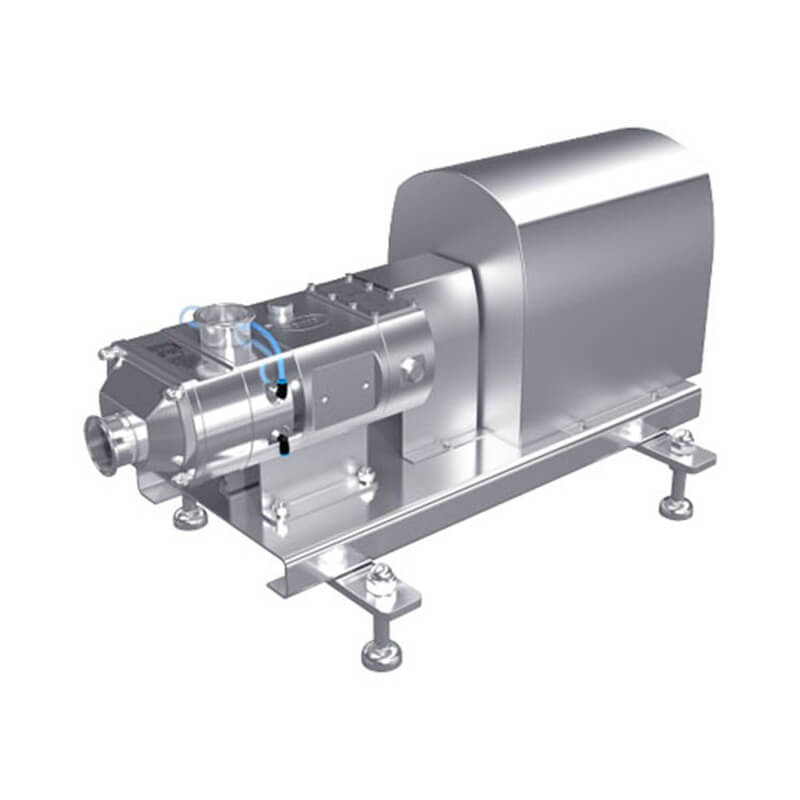

The pump is equipped with helical gearbox and frequency variable motor. According to the user’s needs, can set and edit the inverter, also can be automatically controlled by PLC programming.

Choose the right screw spacing for your process

Option1: Large screw spacing, larger flow rate, ability to deliver larger particles, but the pressure will be lower compared with the small spacing screw.

Option2: Small screw spacing, lower flow rate, but higher pressure, the particles that can be delivered will also be smaller.

Sanitary Twin Screw Pump Structure

Sanitary double screw pump mechanical seal

Sanitary Twin Screw Pump Feature:

● Pulse-free, Low Noise

● High pressure to 300psi (20 bar)

● Special screw lock nut designed to extend service life.

● There are no bearings and screws at the area contacting with the medium.

● Large-diameter 17-4PH shaft for higher strength and stiffness, helping to reduce vibration and extend seal life.

● High precision heavy duty needle roller bearings.

● Oil-lubricated bearings can be forward lubrication over the entire speed, temperature and pressure range.

● Hygienic designed according to 3A, FDA standard.

●Sanitary mechanical seal, easy cleaning and maintenance

● Applied to CIP cleaning and SIP sterilization

● Different drives and devices

1) Manual adjustment, continuously variable transmission

2) Variable – frequency motor adjustment

3) Fixed speed output transmission

● The motor utilizes the IEC EN IE2, PTC thermistor.

Sanitary Twin Screw Pump Various Configurations

Sanitary double screw pump connection

Twin-screw pump model

LGR-20-18, LGR20-26, LGR20-39

LGR-30-24, LGR-30-40, LGR30-60

LGR-70-32, LGR-70-54, LGR-70-80

Sanitary Twin Screw Pump Curve

Twin Screw Pump Dimension

Sanitary Twin Screw pump used for hygienic applications:

Food and beverage:

soup , stew, ketchup, vegetables, dressings, chocolate, fat and oil , cream, breweries, wort, soft drink/fruit juice, meat processing.

Dairy:

Cream, milk, cheese curd and whey, cottage cheese, yoghurt.

Personal care and/Cosmetics:

Ointment, extraction, serum, face cream and emulsion, hair styling gels and liquids, dyes and alcohol, soap, cosmetics.

Chemicals / Industrial:

Solvents, paints, fuels, resins, polymers and sludges, oil and lubricants.

Hygienic pump packing

Frequency Ask Question

Please firstly leave message below for product you need and requirement,I will send you quotaion sheet,then choose the transportation way and check cost,we will send you Proforma invoice for confirm,at last make the payment and we will ship the goods to you.

Delivery time depends on quantity and type of products,for valve and pipe fittings regular is about 7-20days. For pump regular is about 15-25days.

For small amount we require 100% before production.For big amount,regularly T/T 30% deposit, 70% before shipment.

By Bank T/T, L/C, By Alibaba Assurance Order accept Credit Card VISA, Mastercard, E-checking, and we could’t accept Paypal.