O-ring seal is a small thing, but it’s a critical thing to have a significant impact on the sanitary valve. Low-quality seal or inappropriate application can cause many problems E.g. leaking, swelling or cracking. It will affect valve lifetime.

Types of O-ring seal

- EPDM rubber (ethylene propylene diene monomer rubber)is a type of synthetic rubber that is used in many applications.

- Teflon(PTFE) Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene that has numerous applications.

- Viton(FPM) Viton is a brand of FKM, a synthetic rubber and fluoropolymer elastomer commonly used in seals, chemical-resistant gloves, and other molded or extruded goods.

- Silicon rubber is an elastomer (rubber-like material), usually used in pharmaceutical industry.

- NBR Nitrile rubber, also known as nitrile butadiene rubber, NBR, Buna-N, and acrylonitrile butadiene rubber, is a synthetic rubber derived from acrylonitrile (ACN) and butadiene.

The standard of O-ring seal for the sanitary valve

Food and Drug Administration (FDA) standards are applied for O-ring seal to use in food and beverage,dairy, brewing, pharmaceutical industries.

The temperature and chemical compatibility

| Types | Temperature | Chemical Compatibility |

| EPDM | -10 – 130 °C (14 – 266°F) | good resistance to acid and alkali, good abrasive resistance |

| Teflon(PTFE) | -20 – 150 °C (-4 – 302°F) | good resistance to acid and alkali,better abrasive resistance,inelastic material |

| Viton(FPM) | -10 – 130 °C (14 – 266°F) | great resistance to acid and alkali, ozone |

| Silicon rubber | -30 – 150 °C (-22 – 302°F) | bad resistance to acid and alkali, |

| NBR | -5 – 100 °C (23 – 212°F) | the best use for oil or fat products, good resistance to acid and alkali |

DONJOY Sanitary Ball Valve PTFE seat

The Teflon(PTFE) has higher hardness, fully PTFE encapsulated ball valve ability to work high temperature for a long time.it’s suitable to use for sanitary ball valve not suit use for butterfly seal.

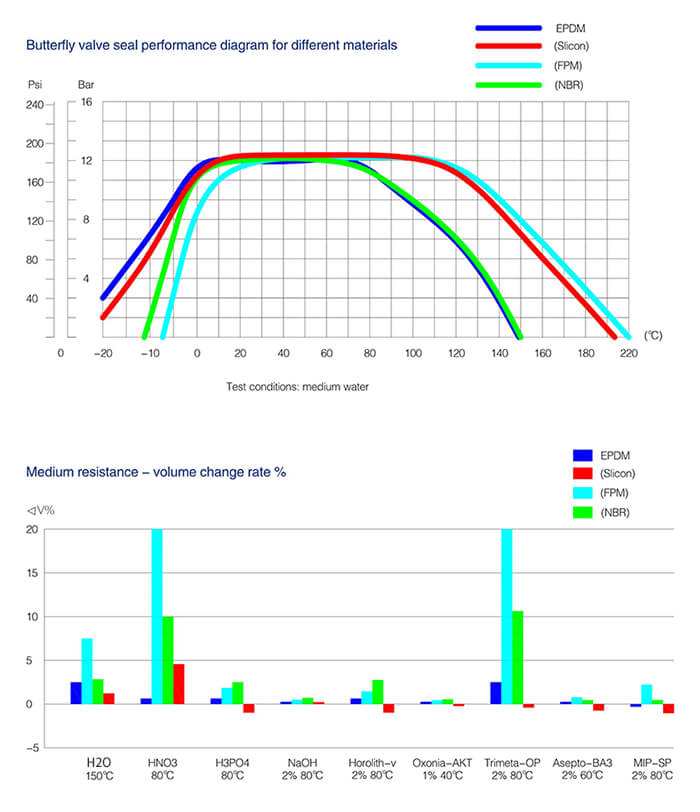

DONJOY Butterfly Valve O-ring Seal performance

DONJOY Sanitary Diaphragm Valve Gasket

In addition to the valve body, the gasket is the only direct contact with media parts. Diaphragm valves rely on a diaphragm membrane to isolate the medium from the actuator and the external air. The diaphragm is also a moving part, the membrane moves up and down by the diaphragm to control the flow of the medium or cut off.

Donjoy diaphragms valve membrane has been developed and tested over many years according to our own testing methods and standards and under strict third party specifications.

Single diaphragm seal

The rubber diaphragm is embedded with a layer of vulcanised fibres to enhance its mechanical properties, the diaphragm has high sealing stability at elevated pressures and temperatures and the reinforcing fibres are hardened on the stainless steel bolts, thus ensuring a better bonding of the rubber to the metal.

- Specification 1”-4” DN20-DN100

- EPDM -10 – 120 °C (14 – 248°F)

Double adhesive diaphragm seal

PTFE diaphragm is highly resistant to chemicals, extremely stable, resilient, long-lasting, highly leak-tight, non-cold degradable and have excellent resistance to temperature fluctuations, whether in hot, cold or steam sterilisation systems.

- Specification 1”-3” DN20-DN80

- PTFE+EPDM -20 – 120 °C (-4 – 248°F)

Double separately diaphragm seal

The diaphragm consists of EPDM and PTFE. The special feature of the modified diaphragm is that the diaphragm itself is shaped to seal against the valve body when the valve is in the closed position, thus reducing the diaphragm load and extending its service life. The diaphragm can withstand higher temperatures and severe working conditions.

- Specification 1/2”-4” DN10-DN100

- PTFE+EPDM -20 – 150 °C (-4 – 302°F)

2 thoughts on “How to select O-ring Seal for Sanitary Valve”

There is noticeably a bundle to learn about this. I assume you made certain good points in features also.

Very interesting points you have remarked, thanks for posting.