Lockable Sanitary Diaphragm Valve

Donjoy Technology offers lockable sanitary Diaphragm Valves. It’s designed with a locking mechanism at the valve stem position. When we turn the handwheel to control the valve stem to move the valve disc to the desired position, we only need to operate the locking mechanism to fix the valve disc to ensure that it will not move at will, suitable for use in aseptic areas or the pharmaceutical industries, Prevent leakage risks or adjustment deviations caused by accidental valve loosening, which may affect production quality or cause safety accidents

Details about Lockable Sanitary Diaphragm Valve

Specification

| Size | DN6-DN100, 1/4" to 4" |

|---|---|

| Body Material | AISI 316L, (EN1.4301/EN1.4404).ASME BPE 316L, or 1.4435-BN2 (316L) Fe<0.5% Forged Body |

| Temperature | -20℃ to +150 ℃ |

| Max pressure | 145psi (10bar) |

| Seal | EPDM+PTFE double seal, EPDM, Teflon PTFE, FPM, Silicon |

| Pipe Joint Systems | DIN SMS RJT 3A ISO IDF |

| Operation | Manual, pneumatic, electric all interchange |

| Surface treatment | Ra16-32µin (0.4-0.8µm), Ra 32µin (0.8µm) as default. |

| Certification | US 3-A, FDA, CE PED/2014/68/EC, Certification |

| Connection type | Tri-Clover/ Clamp End, Thread End, Butt Weld End |

Lockable Sanitary Diaphragm Valve

Donjoy Technology offers lockable sanitary Diaphragm Valves. It’s designed with a locking mechanism at the valve stem position. When we turn the handwheel to control the valve stem to move the valve disc to the desired position, we only need to operate the locking mechanism to fix the valve disc to ensure that it will not move at will, suitable for use in aseptic areas or the pharmaceutical industries, Prevent leakage risks or adjustment deviations caused by accidental valve loosening, which may affect production quality or cause safety accidents

Locking Mechanisms in Manual Diaphragm Valves: A Technical Deep Dive

For engineers and plant managers in critical process industries—chemical, pharmaceutical, and water treatment—valve integrity isn’t just a best practice; it’s a non-negotiable component of operational safety and product quality. The inherent vulnerability of traditional manual valves to displacement from pressure fluctuations, system vibration, or incidental contact presents a persistent risk. Consequences range from minor deviations in production quality to catastrophic safety failures.

The Engineering Challenge: Maintaining Stem Position Under Dynamic Conditions

Standard manual diaphragm valves rely on operator setting and friction to maintain disc position. However, in dynamic operating environments, this approach proves insufficient. The resulting micro-movements or macro-shifts of the valve stem can compromise the entire process loop.

Engineering a Solution: Integrated Stem Locking Mechanism

Our approach addresses this fundamental flaw through an engineered lockable manual diaphragm valve. The core innovation is a positive mechanical locking mechanism integrated directly within the valve stem assembly.

Here’s how it works from a technical standpoint:

-

Precision Positioning: The operator rotates the handwheel, driving the valve stem and positioning the disc with standard precision.

-

Positive Lock Engagement: Once the target position is achieved, the integrated locking mechanism is engaged. This action directly immobilizes the stem, creating a rigid mechanical lock that prevents both rotational and axial movement.

-

Assured Position Integrity: The locked stem ensures the disc remains fixed in its designated position, immune to external forces such as pipeline vibration, pressure surges, or accidental impact.

Key Differentiator: Precision and Repeatability

The critical distinction from standard manual valves is this valve’s ability to precisely control and, most importantly, lock the disc position. This transforms it from a simple shut-off device into a repeatable, precise control element. For processes requiring strict adherence to flow coefficients or exact media containment, this provides a level of flexibility and accuracy previously unavailable in a standard manual valve.

Conclusion

In applications where process deviation is not an option, this lockable manual diaphragm valve provides a deterministic solution for fluid control. It delivers not just a mechanical function, but verifiable safety and repeatable precision for the most demanding industrial environments.

Precision Control in Process Industries: How Lockable Valves Are Revolutionizing Flow & Pressure Management

In high-stakes manufacturing, “close enough” isn’t good enough. Precise control over flow and pressure parameters is not an operational preference—it’s a fundamental determinant of product quality, batch consistency, and overall process efficiency. This is where standard manual valves often fall short, lacking the capability to maintain a set position with absolute certainty.

Enter the lockable manual diaphragm valve—engineered not just for control, but for repeatable, verifiable precision.

The Pharmaceutical Use Case: Where Precision Meets Compliance

Consider pharmaceutical manufacturing. The synthesis of active pharmaceutical ingredients (APIs) or the formulation of biologics requires exacting control over fluid dynamics. Fluctuations in flow or pressure—even those imperceptible on standard gauges—can alter reaction rates, mixture homogeneity, or purification efficacy, ultimately impacting the potency, purity, and stability of the final product.

This is the critical challenge our lockable diaphragm valve addresses.

How It Works in Practice:

-

Calibrated Adjustment: An operator adjusts the handwheel to set the valve disc to the exact opening required by the batch record.

-

Positive Lock Engagement: The integrated locking mechanism is then engaged, mechanically securing the stem and disc in the predetermined position.

-

Elimination of Drift: This lock prevents any deviation caused by system vibration, pressure transients, or incidental contact.

The result is transformative. By enabling truly precise and stable regulation of material flow, these valves directly combat a major source of batch variation. One documented case within a pharmaceutical processing line showed yield rates increasing from 85% to over 95% following the integration of lockable manual diaphragm valves at critical control points.

-

Enhanced Product Quality: Reduced batch rejection rates and improved compliance with stringent regulatory specifications (e.g., FDA, EMA).

-

Reduced Raw Material Waste: Precise dosing minimizes overuse of expensive APIs and excipients.

-

Lower Cost of Quality: Significantly fewer resources are spent on rework, waste disposal, and quality investigations.

Technical Parameters

Size Range: 1″-4″/DN20-DN100

Pressure Range: Full Vacuum to 10 bar

Operating Temperature: -10°C to 120°C (150°C optional)

Applicable Media: Water, oil, gas, and other media

Connection Types: Clamp, Weld, Threaded, Flange

Valve Body Type: Straight/T-Type/U-Type

Steel Components: AISI 304/1.4301 316L/1.4404

ASME BPE Diaphragm Valve Surface finish:

- Wetted interior:

– SF1 Ra 20 (0,51 µm) mechanical polish

– SF2 Ra 25 (0,64 µm) mechanical polish

– SF3 Ra 30 (0,76 µm) mechanical polish

– SF4 Ra 15 (0,38 µm) electro polish

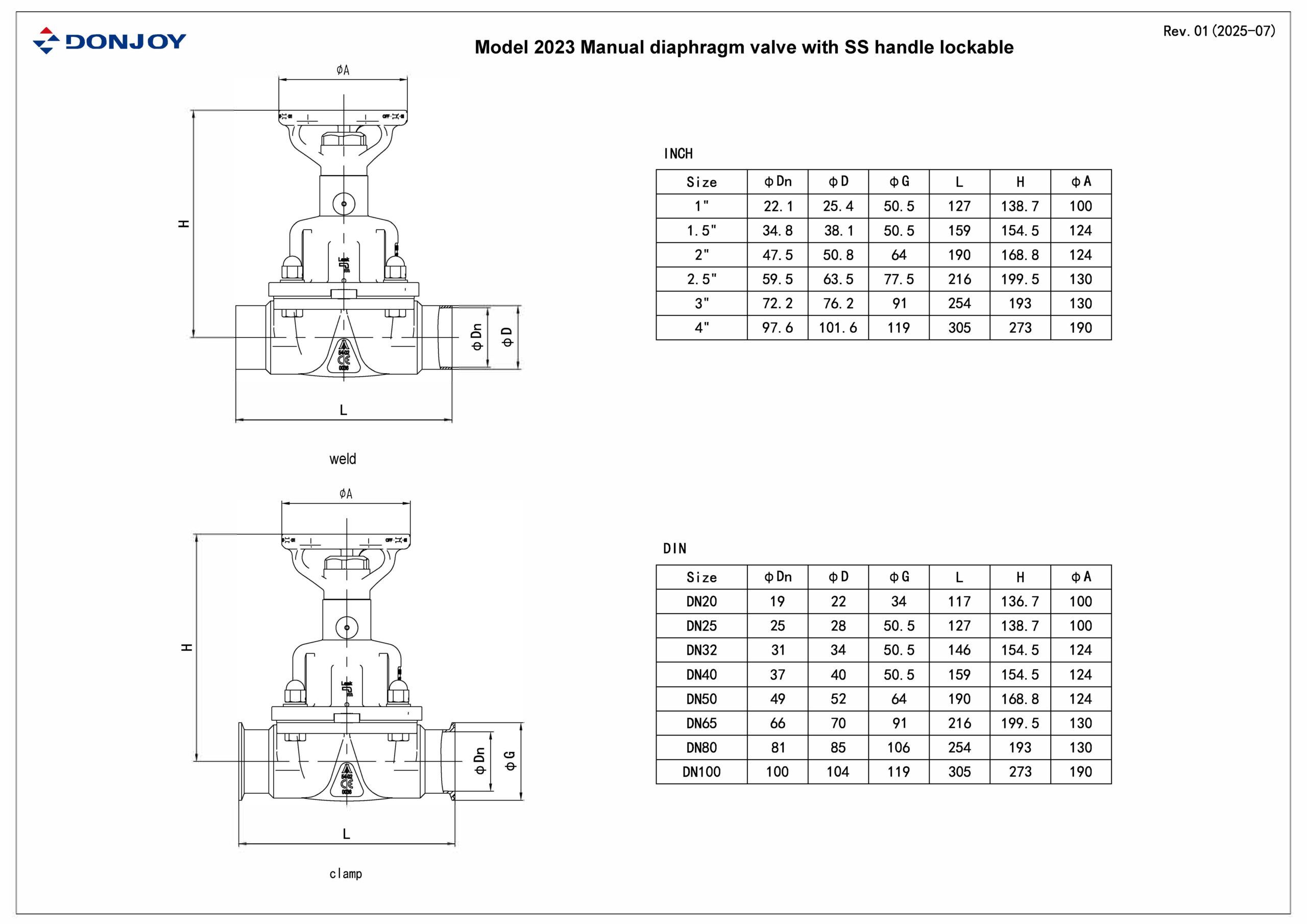

Drawing for model 2023 manual diaphragm valve with a lock

More About O-ring please check the article How to select O-ring Seal for Sanitary Valve

If you need an electrically operated diaphragm valve please check this link.

If you looking for a pneumatic diaphragm valve, please kindly check below product link.

Hygienic valve packing

Our sanitary diaphragm valve used for customer’s pharmaceutical project

Frequency Ask Question

Please firstly leave message below for product you need and requirement,I will send you quotaion sheet,then choose the transportation way and check cost,we will send you Proforma invoice for confirm,at last make the payment and we will ship the goods to you.

Delivery time depends on quantity and type of products,for valve and pipe fittings regular is about 7-20days. For pump regular is about 15-25days.

For small amount we require 100% before production.For big amount,regularly T/T 30% deposit, 70% before shipment.

By Bank T/T, L/C, By Alibaba Assurance Order accept Credit Card VISA, Mastercard, E-checking, and we could’t accept Paypal.