Powder Mixer

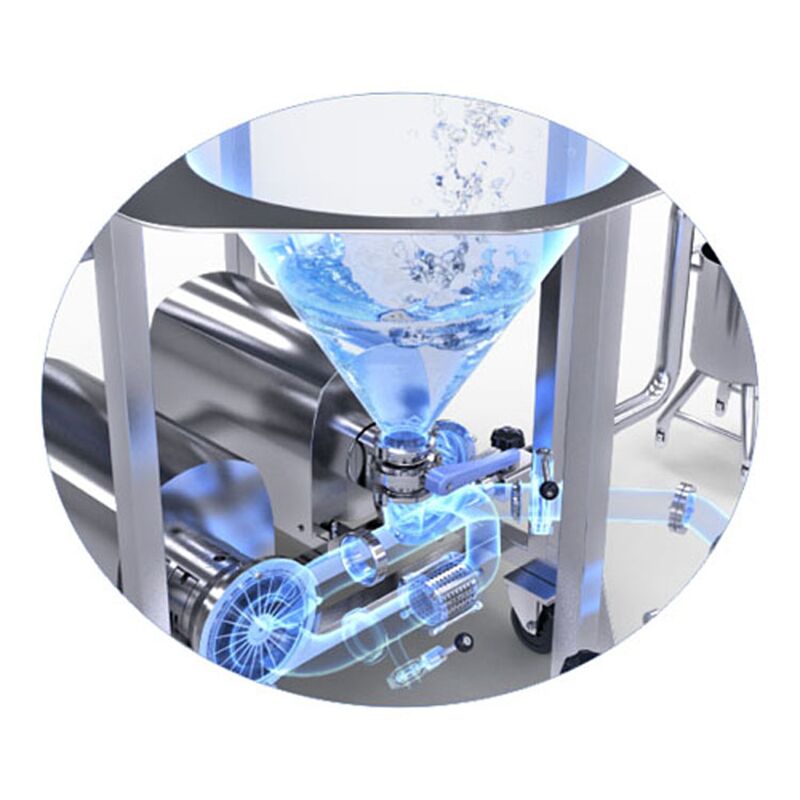

DONJOY Powder mixer is used to mix powders into liquids and with more functions such as mixing, shearing, emulsifying, homogenizing, dispersing, refining, and crushing. It utilizes the self-priming pump in combination with a restricting valve to create a vacuum under a hopper to pull powder into the fluid stream. This vacuum can be maintained throughout the entire production run, ensuring your powder rate will remain consistent and fluid will not plug the funnel.

Traditional funnel-pump powder inductors rely on gravity, vortex or Venturi to push the powder into the fluid stream. These methods all require very specific control of the flow rate to maintain proper induction. As product viscosity changes, the flow rate decreases, causing the pump to clog. Because it is designed to pump entrained air, it will not lose prime or cause fluid to back up in the funnel. The result is consistent flow, no plugging and a well-blended product.

MIXING & BLENDING Optimization

Upgraded and optimized in 2019: with protective motor cover; optimized inlet flow channel; optimized support structure (integrated design); optimized belt pulley fixing method, etc.

Sanitary Powder/Liquid Mixers Structure

- Multiple tasks can be handled simultaneously

- The ratio of liquid and powder is adjustable

- The powder inlet is designed with a valve, which can control the amount of powder inhaled through the valve. The valve can be manual or pneumatic.

- The liquid inlet is designed with a valve, and the liquid can be sucked through the valve to control the flow rate.

- A vibrator is designed on the side of the hopper to prevent powder accumulation

- The hopper can be equipped with a tuning fork sensor, which can prevent the powder from overflowing the hopper and the powder amount is too low to cause the mixture ratio to be inconsistent during automatic operation

DONJOY MIXING & BLENDING PMTU Configurations

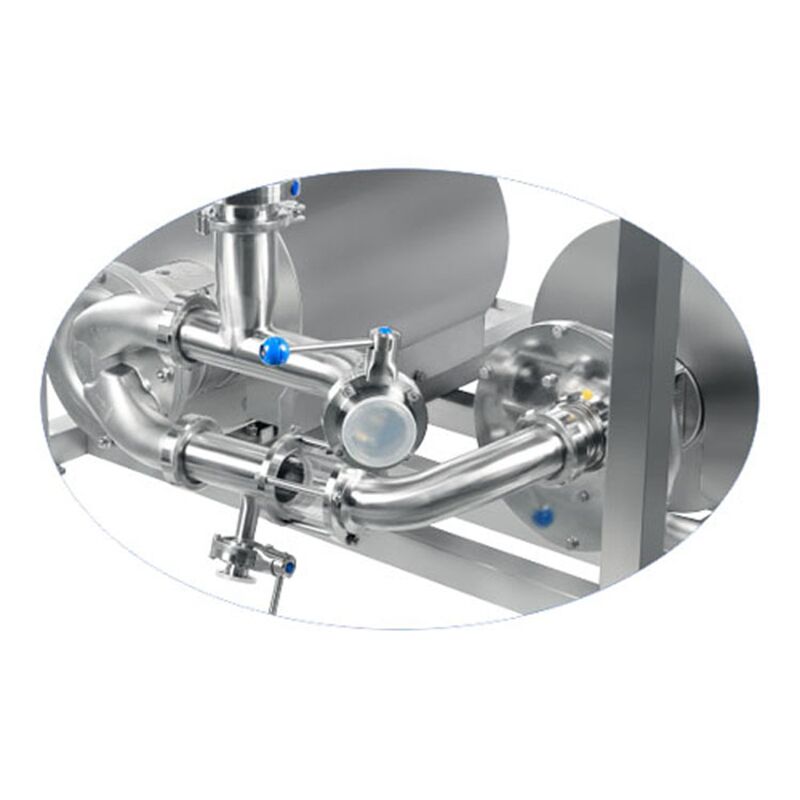

It consists of a rotary lobe pump and a homogenizer

Sanitary Powder Mixer PMTU Selection Table

DONJOY Powder Mixer Control Box